Soluções personalizadas para manutenção de trilhos

JG180LT Crawler Ballast Regulator - 18-Ton Heavy-Duty Railway Track Maintenance Excavator

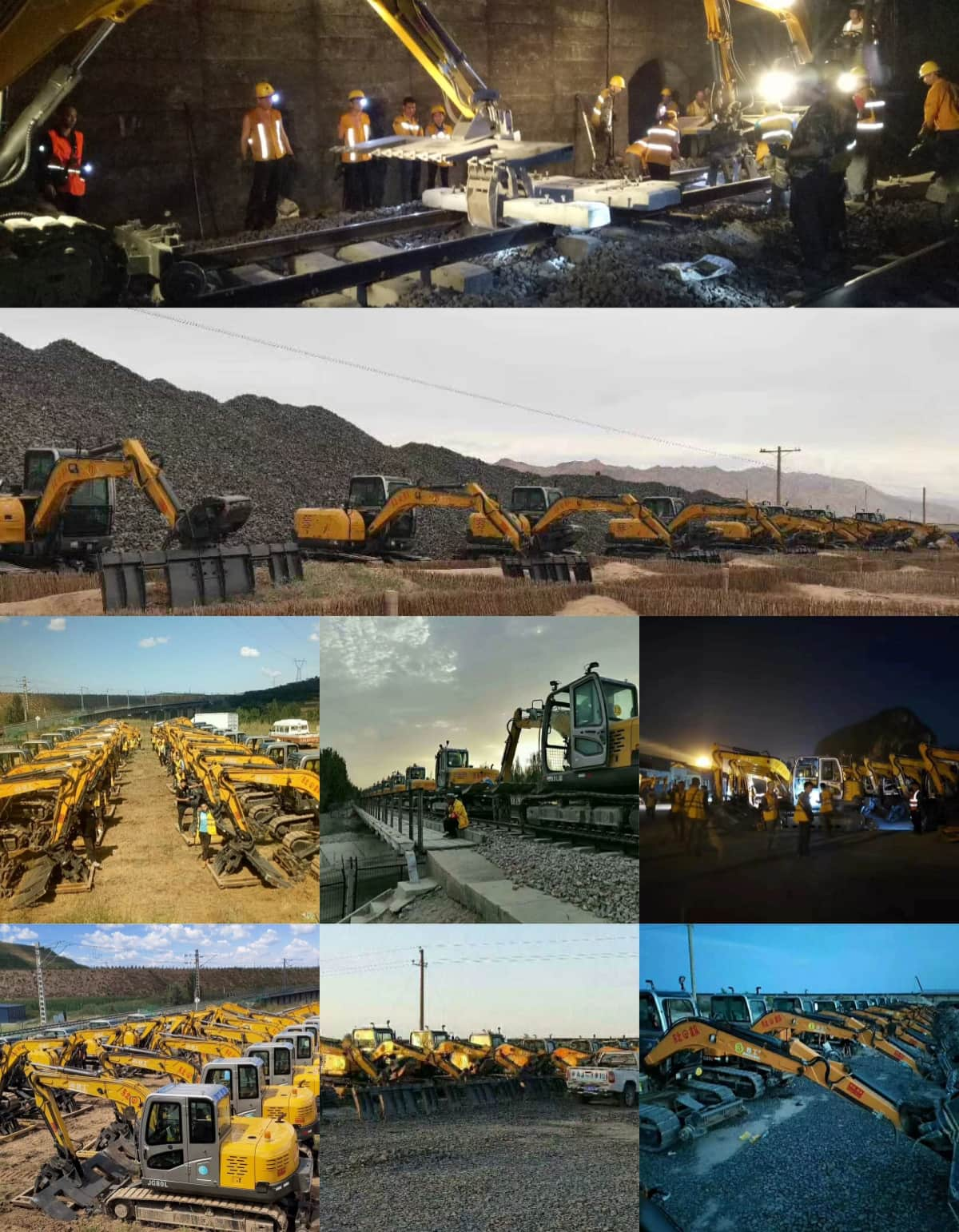

As the backbone force for railway network maintenance, JG180LT is specifically designed for complex ballast engineering. Its low-center-of-gravity crawler chassis and reinforced anti-overturning structure enable stable operation on steep embankments and wet tracks, precisely performing ballast cleaning, sleeper gap filling, and roadbed contour reshaping. The patented hydraulic system integrates multi-level flow control to achieve micrometer-level bucket operation accuracy, ensuring uniform distribution of crushed stones and precise restoration of under-track support force, significantly reducing the risk of track settlement after train passage. The narrow body design also enables seamless entry into the extreme spaces between existing tracks and isolation fences, completely solving the industry pain point of inaccessible blind areas that traditional equipment cannot reach.

Item nº :

JG-180LTPedido (MOQ) :

1Pagamento :

L/C or T/TOrigem do produto :

ChinaCor :

yellowPorto de embarque :

xiamenTempo de espera :

15-45daysPeso :

18000kgThis excavator adopts advanced technology, can quickly complete the task of ballastdigging, greatly shorten the project time, ensure efficient and smooth railway maintenance, suitable for a variety of complex operating environments.The robust and reliable structure of the airframe can adapt to adverse weather and rough terrain, reduce maintenance requirements and extend service life, making it ideal for long-term railway operation.It is equipped with adjustable tools and accessories to easily switch between different mining modes to meet various needs such as ballast cleaning, loading and repair, and improve overall work efficiency.

|

Tech performance and specification |

|

|

(Length*width*height)Transport dimensions |

6100*2200*2650mm |

|

Axle base |

2600mm |

|

Track gauge |

1570mm |

|

Width Of Crawler |

400mm |

|

Ground clearance of counterweight |

780mm |

|

Min ground clearance |

280mm |

|

Angle of rotation |

360° |

|

Rated Power |

48~55KW |

|

Rated Speed |

2200~2300r/min |

Product Overview

JG180LT 18-ton railway track bed maintenance crawler-type excavator

Breaking through the limitations of a single function, the modular quick-change system enables the equipment to switch to the "all-rounder" of the track bed in seconds - when paired with a ballast scraper, it can efficiently level the crushed stone layer; when connected to a hydraulic tamper, it can compact the loose roadbed; when equipped with a crushing hammer, it can immediately remove the rock that invades the track. The intelligent cockpit is equipped with anti-vibration suspended seats and night vision panoramic monitoring, ensuring zero blind spots in the operating field even in the dim environment of the tunnel or during continuous seismic operations. The triple safety protection core (automatic slope compensation + emergency braking + ground pressure monitoring) also gives it reliable protection in extreme conditions such as heavy rain and frost, allowing maintenance operations to break through the traditional boundaries of climate and terrain.

Product Advantages

Efficiency:This excavator adopts advanced technology, can quickly complete the task of ballastdigging, greatly shorten the project time, ensure efficient and smooth railway maintenance, suitable for a variety of complex operating environments.

Durability:The robust and reliable structure of the airframe can adapt to adverse weather and rough terrain, reduce maintenance requirements and extend service life, making it ideal for long-term railway operation.

Flexible:It is equipped with adjustable tools and accessories to easily switch between different mining modes to meet various needs such as ballast cleaning, loading and repair, and improve overall work efficiency.

Application scenarios

Q&A

Q: Which railway environment is this excavator suitable for?

A: It is designed for a variety of railway conditions, including mountain, plain and narrow track areas, to cope with different terrain challenges and ensure stable operation.

Q: How does it handle ballast cleaning?

A: Special digging tools are used to clean and load ballast efficiently, reduce manual intervention, and maintain track leveling and drainage performance.

Q: Is it easy to operate and maintain?

A: Yes, humanized design, easy to operate, and equipped with intelligent diagnosis system, the maintenance process is simple and quick, reducing the risk of downtime.

Q: What are its security features?

A: Built-in multiple safety protection mechanisms, such as anti-overturning design and emergency braking system, ensure the safety of operators and railway equipment.

Q: Do you support customized attachments?

A: Yes, it can be flexibly matched with various mining tools, such as bucket or crusher, to adapt to different engineering needs and enhance product versatility.